| Spot UV coating |

| UV inkjet technology |

- MGI’s exclusive inkjet engine technology.

- Drop-on-demand (Dod) inkjet application.

- Piezoelectric print heads in single pass printing.

- Flexible & scalable architecture.

|

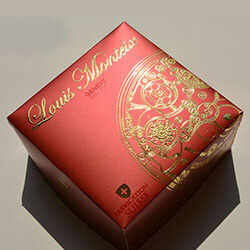

| Coating thicknesses |

Depending on your file and the substrate used, the coating thickness can vary from a traditional flat spot UV coating of 3* microns (µm) up to 232* µm for 3D raised texture effects and a tactile finish.

* confirm substrate/lamintation/toner/metallic film compatibility with MGI.

|

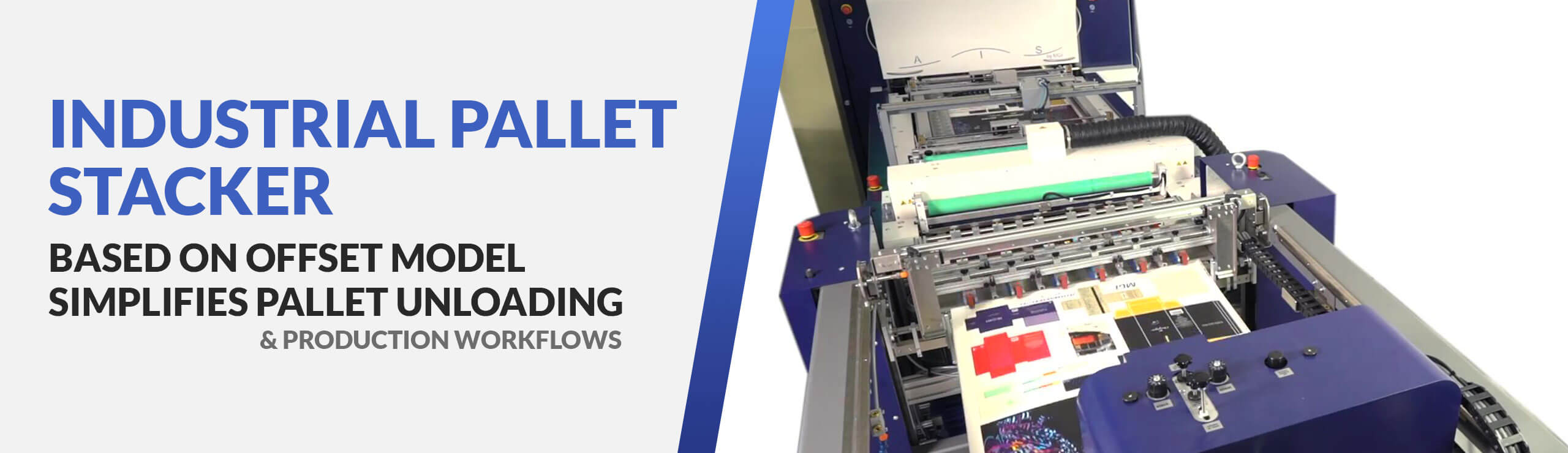

| Production speed |

The default sheet size is ISO B2 unless otherwise stated.

Up to 3,123* B2 sheets size per hour for all versions.

Up to 4,200* ** B2 sheets per hour with a landscape rotation of the sheet.

Up to 2,291* ** B1 sheets size per hour.

* speed will vary according to printing parameter used.

** with the 75cm/ 29’’ Evo kit. |

| Registration |

Left & right motorized registration side guides. Automatic registration using the built-in AIS SmartSanner technology for real-time management of entire sheet. No registration marks required.

Overall registration of ± 200 microns. |

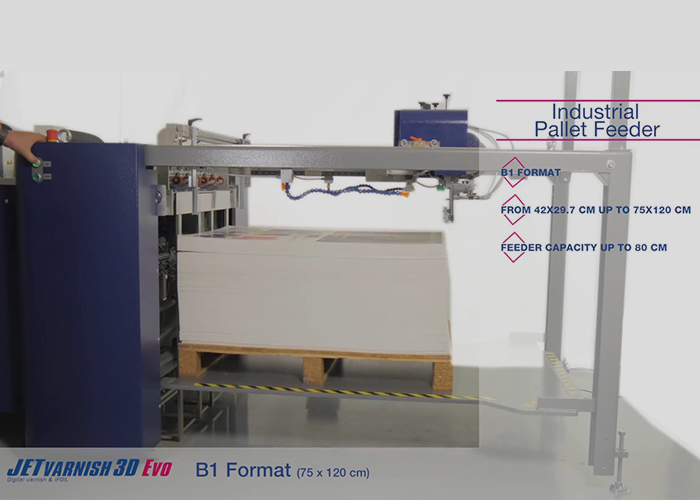

| Formats |

Min: 42x29.7 cm / 16.5x11.5’’ (width x length)

Max: 52x120 cm / 20x47’’ (standard)

75x120 cm / 29x47’’ *

* depending on the configuration selected. |

| Paper thickness |

Motorized inkjet head height-adjustment

Min: 135 gsm and not less than 150 µm / 6 mil before printing & lamination.

Max: Up to 800* gsm. Compatible with folding carton.

* with pallet feeder & stacker options |

| Substrates |

Enhancement on most* matte or glossy laminated surfaces, with or without aqueous coating, layered paper, plastic, PVC and other coated materials.

Spot 3D coat directly onto most* digital prints (ie. MGI Meteor).

* confirm substrate/lamination/toner/metallic film compatibility with MGI. |

| Printing width |

51 cm / 20’’ (standard)

56 cm / 22’’ *

63 cm / 24.8’’ *

74 cm / 29’’ *

* depending on the configuration selected. |

| UV coatings and yields |

The JETvarnish 3D Evo comes standard with 1 coating tank for both 2D & 3D applications.

The varnish tank is having a high capacity volume (18 liters/4.7 US gal.).

“On-the-fly” tank changeover possible during production without any interruption and no waste. |

| iFOIL (hot foiling) |

Optional digital hot foiling module application standard sheet format is B2 ISO

- Production speed

Up to 2,300* ** B2 (length size) sheets size per hour (or up to 25 m per minute - 65.6ft per minute).

- Films

Optimization system of film consumption.

- Film rolls

Max. roll diameter and length : ± 30 cm/11.8’’ and from 400 to 2,000 meters of film (1,300 to 6,500 ft).

Up to 5 simultaneous film rolls on the same axis (with a minimum of 10 cm/3.9’’ per roll)

2 cores available : 1 inch as standard and 3 inches as option.

- Maximum Surface

Hot foil substrate surface can not exceed 74x119 cm (29.1x46.8’’)**.

- Embossing

2D & 3D hot foil raised effects

The surface of the metallized film may be covered with a layer of varnish or another foil.

- Dry air

Requires air without oil at 6 bar (87 psi) & 24 m3/h (14 cfm) supply.

* speed will vary according to printing parameter used.

** with the 75cm/ 29’’ Evo kit.

|

| Other options |

Corona* ** substrates treatment module

In-line system made to optimize varnish adhesion on complex printed substrates

Variable Data Enhancement (VDE)

Manage and edit files on the workstation

Full variable data (text, graphic, image) for both 2D/3D spot coating and hot foiling areas

Integrated barcode (1D/2D) reader system & controller

Raster Image Processor (RIP) as an option

* recommended on substrate above 42 cm width.

** recommended on paper above 250 Gsm / 250 µm.

|

| Dimensions (L x W x H) & weight |

Up to (LxWxH) 12.72x1.93x1.84 meters/41.73x5.81x6 ft (Evo 75 full options)

Necessary clearance: 1 meter (3.3ft) on 3 sides and 2 meters (6.6ft) on the stacker side.

Up to ± 4,434 kg (Evo 75 full options) |

| Operating environment |

Electrical requirements

- JETvarnish 3D Evo

400 Volts - 50/60 Hz, 32A (63A plug)

-

iFOIL L

400 Volts - 50/60 Hz, 25A (32A plug)

Operating environment

Temperature : 18 to 30°C / 64 to 86°F

Relative humidity between 30 and 50%

(no condensation) |

| Eco friendly |

- Enhanced UV protection with lower energy consumption than traditional UV systems.

- No makeready, no plates (offset), no screens (silkscreen), no dies (hot foiling), no waste (electricity, paper, varnish and time).

- No cleaning steps between jobs (automatic inkjet head cleaning system). Reduction of consumables (elimination of many plastics).

|