Discover Konica Minolta

Back

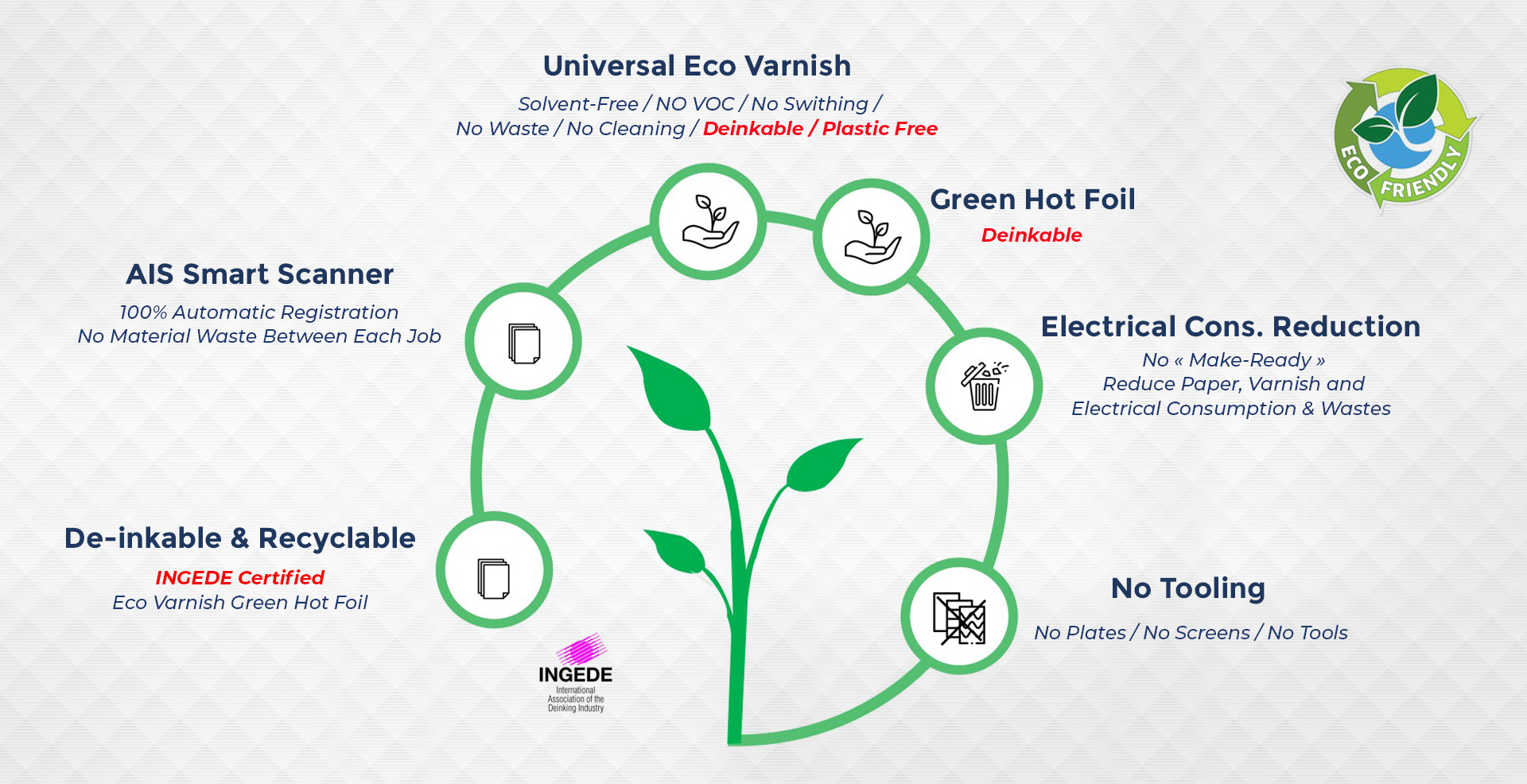

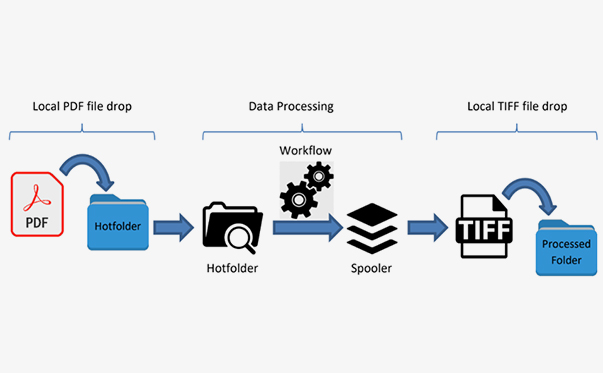

Integrated solutions to improve the way you work

Assisting businesses to leap into the world of Digital Transformation. Browse through our range of Office Multifunctional Printers, Production Printers & Industrial Printers.

Empowering businesses with futuristic Printing Solutions since 2012.

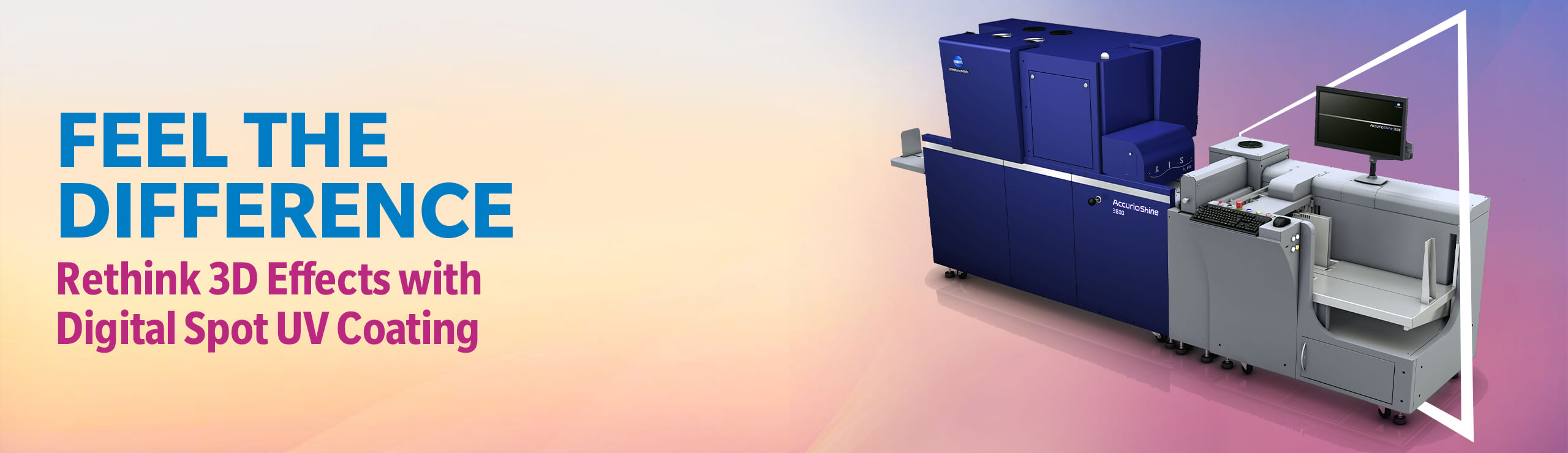

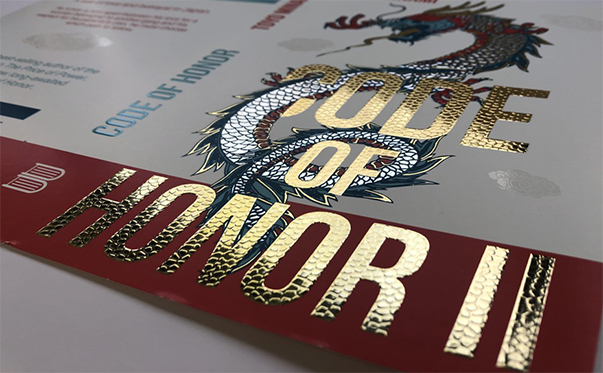

Giving shape to ideas

In a world that's changing at a faster rate than ever before, Konica Minolta gives shape to Ideas that help create a better future for our customers and society.

Corporate Responsibility

Careers

Learn more about working at Konica Minolta